- Sydney, NSW

- [email protected]

- ACN: 679 543 901

Australian Glass Standards Fact Sheet

Australian Glass Standards Fact Sheet

NSW Glass Masters / Australian Glass Standards Fact Sheet

No responsibility is accepted by NSW Glass Masters for any non-compliance with these standards.

All glass installed in buildings shall comply with relevant Australian Standards. It is strongly recommended that builders, architects, building designers, and building surveyors ensure evidence is provided. Marking of glass to ensure compliance with AS2208 is mandatory.

The use of monolithic toughened glass more than 5000mm above the finished floor height may be at risk of spontaneous breakage. Toughened glass glazed monolithically should be heat-soaked unless a barrier exists which will prevent fragments from falling and reduce the risk of injury.

An awning or a balcony would be considered a barrier suitable for this purpose. Please refer to AS1288 for further clarification.

1. Doors

•Small panels in doors with 3mm and 4mm annealed glass are permitted to a maximum of 0.1m² and a maximum panel width of 125mm.

•Small panels in doors with 5mm and 6mm annealed glass are permitted to a maximum of 0.26m² with a maximum panel width of 300mm.

•Unframed doors, other than those in bathrooms, shall be glazed with toughened safety glass with a minimum thickness of 10mm.

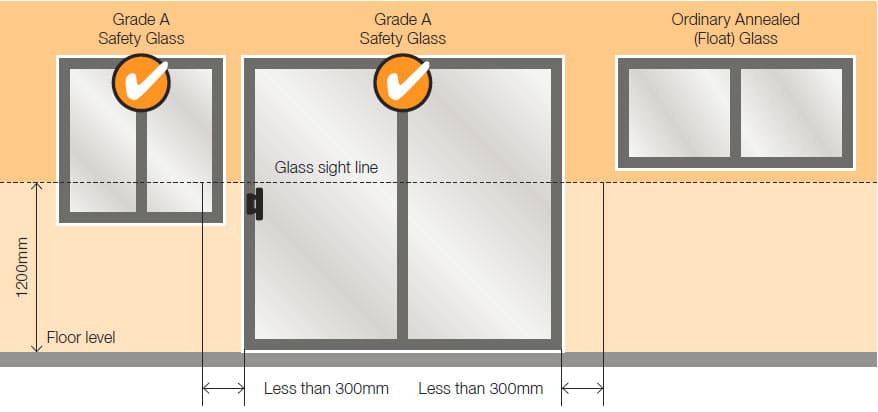

2. Side Panels (Glass which has its vertical sight line within 300mm of door opening)

•A minimum of 5mm ordinary annealed glass may be used up to a maximum area of 0.3m².

•For decorated glass, 3mm and 4mm glass shall not exceed 0.1m² to a maximum panel width of 125mm.

•For decorated glass, 5mm and 6mm glass shall not exceed 0.26m² to a maximum panel width of 300mm.

•Grade A Safety glass to TABLE 5.1 if the panel is within 1200mm from floor or ground level and fully framed.

3. Windows (Low Lights)

•All low-level glazing where the lowest sight line is less than 500mm from the ground or floor level shall be Grade A safety glass to Table 5.1 except:

•In fully framed glazing, ordinary annealed glass not less than 5mm is permitted to a maximum area of 1.2m². Larger areas of ordinary annealed glass are not permitted regardless of glass thickness.

4. Glass which could be mistaken for a doorway or opening

•Ask yourself, “Could anyone mistake the panel for a doorway or opening and potentially walk into the glass?”

•If yes, use Grade A safety glass.

Note: The panel cannot be mistaken if:

•The opening is equal to or less than 500mm wide.

•The lowest sight line is 500mm above the floor.

•The sight size height is less than 1000mm.

•The glazing is opaque or patterned.

•A chair rail is provided with its upper edge not less than 700mm and its top edge not more than 1000mm above the floor level.

•The panels are louvres with a blade width not greater than 230mm.

•There is a difference in floor level of 1000mm.

5. Bathrooms

All glass in bathrooms should use Grade A or B safety glass for fully framed glazing. The only exception is a mirror, which is either fully adhered to the wall or fully protected by a vanity or bench with a minimum height of 760mm and a minimum depth of 300mm.

•Partly framed glazing shall be glazed with Grade A Safety Glass with a minimum thickness of 5mm to an area not exceeding 2.2m².

•Frameless glazing in shower screen doors and returns shall be Grade A toughened or toughened laminate with a minimum thickness of 6mm.

6. Louvre blades subject to risk of human impact

Where Grade A safety glass is required and louvres are used, those louvres shall be Grade A toughened safety glass. A nominal thickness of 5mm up to 230mm in blade width and 1000mm in blade length, e.g., in bathrooms, side panels, aged care, and schools.

7. Two Edge Unframed Glazing

Glazing with two horizontal edges unframed shall be Grade A safety glass and comply with the following:

•5mm toughened to a maximum 1000mm span.

•6mm toughened to a maximum 1200mm span.

•6.38mm laminated to a maximum 750mm span.

8. Stairway Glazing

Glazing, including mirrors in stairways, shall be Grade A safety glass in the following situations:

•Within 2000mm horizontally and at right angles to the bottom riser of each stair flight.

•Within 1000mm and parallel to any part of the stair flight or landing.

•Safety glass is not required where the glazing is protected by a solid barrier not less than 1000mm in height.

9. Making Glass Visible

If the presence of glass is not made visible in a door, side panel, or a panel capable of being mistaken for a doorway or opening and is not made apparent by other means, the glass shall be marked to make it visible.

Marking shall be in the form of an opaque band not less than 20mm in height and located so that the vertical height from the floor level is:

•Not less than 700mm from the upper edges of the band, and

•Not more than 1200mm to the lower edge of the band.

Making glass visible is not a substitute for safety glazing.

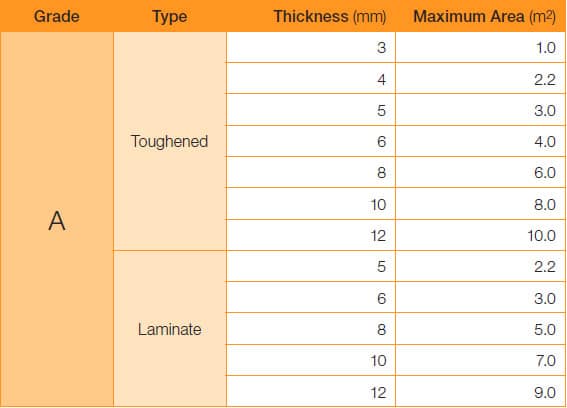

Maximum Areas of Safety Glass

NOTE: Toughened laminate can be substituted where toughened glass is required.

10. Balustrades

All balustrades require an interlinking handrail where the difference in floor level is greater than 1000mm.

Glass in balustrades, which have a load-supporting handrail and use glass infill panels at 1.0kPa and 0.50kN, framed on two opposite sides or fully framed on all four edges, shall be a minimum of:

•8mm toughened glass to a maximum span of 1070mm between supports,

•10mm toughened glass to a maximum span of 1650mm between supports,

•12mm toughened glass to a maximum span of 1930mm between supports.

Span is defined as the distance between supports. For glass supported on all four edges, the span is the smaller dimension.

PLEASE NOTE:

•This guide applies to glass that has a maximum wind load of 1.5 ULS and 0.80 SLS and an aspect ratio not greater than 4.

•It only applies where panels are supported on 4 sides (except where indicated).

•This guide applies to glass that is within 2000mm of ground or floor level.

Disclaimer:

This post has been developed to provide general guidance, awareness, and education. It should not be viewed as a definitive guide. While every effort has been made to ensure all information is accurate, NSW Glass Masters expressly disclaims all and any liability to any person for anything done in reliance on this publication.

This document has been adapted from materials provided by True Blue Glass. No responsibility is accepted by NSW Glass Masters for any mistakes, errors, or omissions in this publication.

Need Help?

Don’t hesitate to contact us for more information and a FREE QUOTE.